The 2GRFE 3.5 liter V6 has been finding its way into the MR2 platform for almost a decade now. With the support of great vendors like Frankenstein, Wilhelm, TCS, and ATS we have seen an absolute surge in popularity. Now it is relatively easy to achieve 280whp/350 horsepower with a bolt in swap. 280whp may sound like old school Gen3 3SGTE power numbers, but the drag strip times (and road course times) are reminding us that it is power under the curve, not just peak numbers. At NA2022 we saw Caleb Purdy and Lee Perez race down the 1/4 mile side by side for 10-15 passes. Caleb would win one, Lee would win the next two, then Caleb again. I don't recall who tallied the most wins, but the times were almost identical in ET and trap speed. Caleb's car is a 2GRFE swap. Lee's setup at the time was a proven 350whp gen5 3SGTE setup with standalone ecu and a CT16 turbo upgrade.

The thought of 280whp does not quicken the pulse of the 450whp four cylinder guys. Launce Bennett set the compressor wheel in motion when he asked ATS Racing to turbo his 2GRFE. The initial results were great, almost 500whp on pump gas. That's a number that previously required E85 or race fuel on a four cylinder. When we switched to E85 (and a better intercooler) we saw 650whp. We've done over a dozen of these now. Each one making over 600whp. We even flew to TCS in 2023 to tune Ty's personal 2GRFE turbo car. But don't misunderstand, at this level the stock 2GRFE is very unforgiving. One mistake in tuning can be disastrous. At ATS we tend to push our own cars harder than client cars, especially me. If something is going to fail, I want it to happen to me and not a client. Collectively we have destroyed at least five 2GRFEs. The good news is we are learning from each one so that we can offer a better product.

So you are finally getting to the meat of this blog entry:

Rods - these aren't gen2 3SGTE rods. More like Gen4/5 rods.

How we cope: using rpm dependent boost control we limit peak torque. Or aftermarket rods, we still use rpm dependent boost for traction reasons, but Aaron's car saw 700lb ft of torque at 5000rpm recently.

What's the safe number on a stock rod? about 500lb ft.

Piston rings - The ring gaps are TIGHT and don't cope well with the additional heat from the turbo. The heat causes them to expand, then the ends touch tips aggressively. Then the ring buckles and cracks the piston.

How we cope: On pump gas we have to run an extremely rich mixture to keep cylinder temps low. E85 is a HUGE help. We still run it a little rich for safety though. Another solution is to pull the pistons out of the block, regap the rings to a larger value and reinstall. It's free (except head gaskets and head studs) if you are DIY, but labor intensive.

What's the safe number? - 500whp on pump gas is safe on the street, it's even safe on a 1/8 mile drag strip. I don't think it's safe on a full 1/4 mile pass. On Ethanol it's basically a non-issue.

Pistons - not only are the ring gaps TIGHT, but so are the clearances between the piston and the cylinder wall. Proper care has to be taken to make sure the car is fully warmed up before driven hard. What happens is the pistons heat up faster than the cylinders, so the pistons grow slightly. If you put too much heat in them too soon the pistons will expand until it touches the cylinder wall. Best case this causes mild scoring. Worse case this causes enough scoring that aluminum is scraped off and lands in the ring area and jams up the rings. This causes a loss of compression and is basically fatal to the block and pistons.

How do we cope: Let the car warm up fully before aggressive use.

What's the safe number? - Not really an issue once fully warmed up

A great way to solve the piston and piston ring issue is to upgrade to forged pistons. You'll end up with a much stronger package overall.

Valvetrain 1 - This isn't the high RPM flawless valve train of the 3SGTE. It's got rocker arms and high efficiency valve springs.

How we cope - our initial solution was the MWR upgraded lifters and clips only. We still saw a few people throw a rocker off, but no catastrophic failures, and we were able to reinstall the parts and restore performance.

What's the safe number: about 7200-7400rpm. The lifters and clips seem to be worth an extra 200rpm though.

Valvetrain 2 - on some of the turbo cars we see a weird dip right around 6000-6500rpm. Some cars recover quickly from it, some don't. Aaron's car was one of the worst. I should mention here that there are at least three different 2GR valve train setups, there are wide rockers, skinny rockers, probably multiple valve spring revisions etc. I have yet to find a pattern to exactly what motor has what. None are that great so I don't see a point in trying to find a donor engine that came from a blue Sienna made on a Tuesday because it's supposed to have these "best" valvetrain.

How we cope - we tried a number of things, eventually we discovered it is valve float. Why it happens at that rpm and how it recovered at a higher rpm is a mystery to me. My guess is that it's some sort of harmonic in the valve spring. The good news is that upgraded valve springs solved the issue.

Head bolts - these are one time use. Seriously. Don't buy off-brand bolts either. I found this out in an expensive way. If you need new ones just jump up to ARP head studs.

Where we are now: I sold my 800+whp 2.3 superstroker setup in 2022. It is an amazing drivetrain package and bulletproof at that power level. But the big cams, huge injectors, massive cam overlap, not enough vacuum for the brakes to work right, etc caused a bunch of sacrifices in driveability. The 2GRFE Turbo package even at 750whp still idles and cruises like a stock camry! The only issue I have is that a twin disk clutch is required at this power level. The low end torque right off idle does make that MUCH EASIER to deal with however.

My current 2GRFE engine is the following:

Wiseco stock bore, stock compression pistons - these are a drop in piston that does not require months of waiting at the machine shop. However I am seeing a little smoke on start up from the larger ring gaps and loose pistons. Small sacrifice IMO

BC rods

MWR valve springs

MWR lifters and clips - not 100% sure if these are necessary with the valve springs, but I know they are compatible at this pointARP head studs

Felpro head gaskets - we may look into a different head gasket with larger cooling passages in the future, but so far so good with this one

Clutchmaster twin disk clutch (street version with steel flywheel)

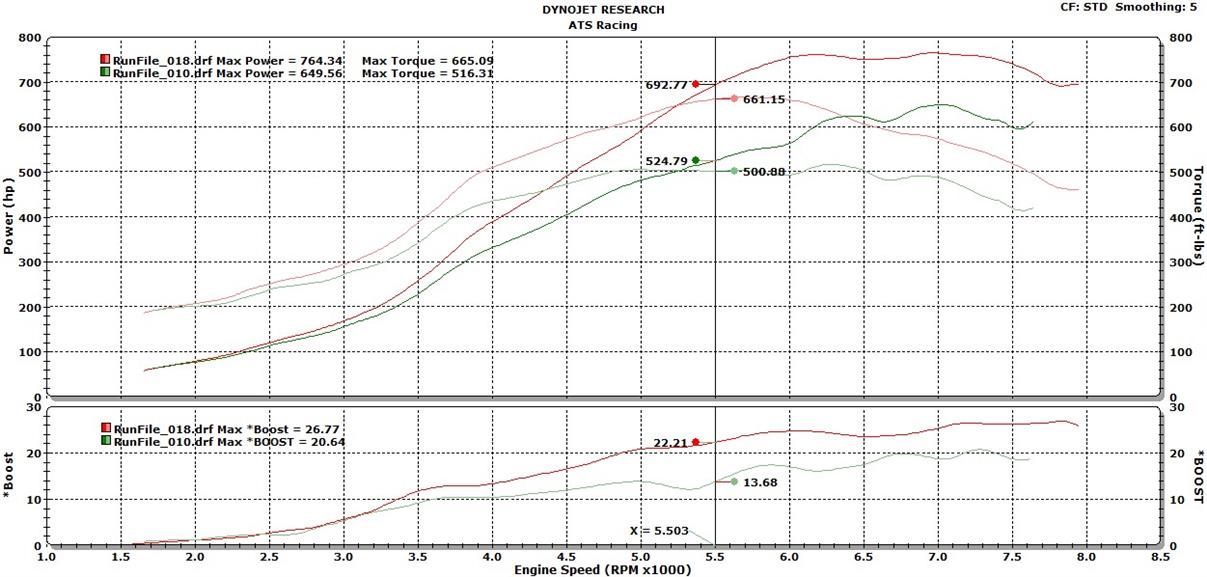

I'm pretty confident this is a 900whp capable setup except I would need a larger turbo, larger cams, and probably one of Marc's billet intake manifolds. Instead we used the upgraded parts to run the boost in sooner giving us a massive 160lb ft boost of torque at 5500rpm. As it is right now it's a 750whp BEAST that my wife is happy to jump in and drive. Below is a comparison of my old setup (stock long block with lifters and clips) in green versus the current "built motor" setup in red.